Blog

-

- February 23, 2025

Signal conditioners are vital components in many industrial systems. They process, convert, and protect signals so that data stays clear and reliable. They boost weak signals and reduce noise to keep your system running smoothly. In this guide, we examine the different types of signal conditioners and the key features you should consider. This way, you choose the best solution for your industrial needs.

You can use these devices in many settings. They ensure every part of your system gets a clean and accurate signal. Our experts at US Automation Controls are here to provide you with a comprehensive guide. Let's begin!

What Are Signal Conditioners?

Signal conditioners are devices that modify signals to improve their quality before they reach critical processing equipment. They may amplify weak signals, filter out noise, or convert signals to a more usable format. By doing so, signal conditioners help maintain the integrity of data and ensure smooth operation in both small repairs and large-scale

-

- January 23, 2025

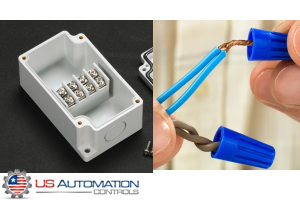

Electrical connections play a critical role in ensuring the safety, performance, and longevity of wiring systems, especially in demanding industrial settings. Two of the most commonly used connectors are terminal blocks and wire nuts. While both serve to join electrical wires, their features, applications, and durability make them suitable for very different purposes. If you’re considering which to use for your industrial wiring project, this guide our professionals will break down their strengths and limitations, helping you make an informed decision.

Understanding Terminal Blocks and Wire Nuts!

Terminal Blocks

Terminal blocks are modular, insulated devices used to secure multiple wires. These connectors are a staple in industrial and commercial applications, particularly for high-voltage systems. Their design allows for stable and durable connections while offering easy access for testing, inspections, and maintenance. Terminal blocks are commonly found in control panels, industrial machinery,

-

- December 23, 2024

If you work around industrial machinery, chances are high that you’ve come across both position switches and limit switches. At first glance, they might seem like two names for the same sensor, but their purposes and capabilities can vary significantly. In this blog, we’ll clarify what makes each type unique, where they overlap, and why having the right device matters for your system. We’ll also explore related terms like the limit switch sensor, the proximity switch, and the proximity limit switch all of which play a critical role in modern automation and it's important to know them all.

Position Switches: What Are They?

Position switches are designed to detect and relay the precise location of a moving part within a mechanical or automated setup. They can rely on contact-based methods (physically touching the object) or non-contact technologies like magnetic or electrical fields. Because they often provide ongoing or incremental data (rather than a simple on/off state), position switches

-

- November 23, 2024

The Secret of Choosing the Right Terminal Blocks

Terminal blocks are essential components in industrial electrical wiring. Whenever you need to join two or more electrical wires safely, terminal blocks are there to save the day. They help facilitate safe and secure connections between different systems, which allows for easier wiring and maintenance. Whether it be repair or scaling, further work in the future is simplified when you use terminal blocks.

However, there are many types of terminal blocks and connectors. How do we know when to use each? That's why we're here. In this article, you will learn how to choose a terminal block based on your use case. Whether you are trying to wire control panels, machinery, or HVAC systems, you'll find your best terminal block choice here. We will go over the different types of terminal blocks, their use cases, and the factors that affect your choice.

This article was brought to you by the reputable automation supplies wholesaler in Short Hills,

-

- October 21, 2024

When you want to choose the best tools and devices for industrial wiring, learning the differences between PLCs and relay-based systems is imperative. Since PLCs and relay logic are both used for industrial automation, choosing the proper control system is crucial to performance and safety in an automated industrial setting. Moreover, other important factors like flexibility, scalability, and cost-effectiveness also depend heavily on whether you choose PLCs or relay-based systems.

In this article, you will read about the differences between PLCs and relay logic, the advantages of PLCs over relay logic, and the use cases where it's wiser to choose a programmable logic controller over a relay-based system.

Know the Difference

Let's dive into the differences between Programmable Logic Controllers (PLCs) and relays. We will discuss the differences between the two from five perspectives:

Control Method

As the key difference between the two control systems, their control methods make much difference

-

- September 23, 2024

Modern industrial settings heavily rely on automation systems to streamline processes, improve efficiency, and ensure consistent results. However, such modern automation systems still have to be operated by humans. Thus, an efficient interaction between humans and machines is essential.

The absence of seamless interaction between humans and machines in industrial settings leads to malfunction, lack of performance, and safety hazards. On the other hand, well-designed human-machine interfaces allow simple interactions with industrial equipment and ensure efficiency, safety, and effectiveness. Some benefits of using high-quality human-machine interfaces are minimizing the learning curve, lowering the risk of accidents, and ensuring performance.

This article will comprehensively introduce industrial automation HMIs and their role in modern automation systems.

What Are Human-Machine Interfaces (HMIs)?

HMIs allow a human to control a single machine or piece of equipment. As a type of user interface

-

- August 23, 2024

PNP and NPN transistors are crucial components in industrial wiring since they control the current flow in circuits. By understanding these two types of transistors well and knowing when and how to convert their output signals, you can significantly benefit from using them. This article will walk you through the most common applications of PNP to NPN converter circuits, explain why you need to use them and provide a guide on how to use them effectively.

What Are PNP and NPN Transistors?

When it comes to any circuit that needs a bipolar junction transistor (BJT), PNP and NPN (respectively "positive-negative-positive" and "negative-positive-negative") transistors are the primary choices. The difference between these two is in the type of charge carriers and the direction of the current flow. Both transistors are activated by a small current being applied to the base. However, in the case of that current being applied, the current flows from the emitter to the collector in a PNP transistor,

-

- July 23, 2024

Industrial wiring is very complex. It involves plenty of cables and connections that can easily get out of hand and become unmanageable if you don’t approach the job systematically. It is essential to make sure the wiring systems are efficient and reliable, to ensure both the performance of the industrial operations and safety. This is where terminal blocks and connectors come into play. Being essential tools for anyone involved in industrial electrical work, they offer an ideal solution for organizing and simplifying wiring tasks. This article will explore the different uses of terminal blocks and connectors, and provide practical tips for their implementation in industrial settings.

What Are Terminal Blocks and Connectors?

Terminal blocks are modular, insulated devices used for connecting multiple wires. They allow for the electrical power and signals to be distributed in an organized way. They come in different types:

- Screw terminals that use screws to clamp the wires.

- Spring-clamp terminals

-

- June 23, 2024

Industrial automation has revolutionized manufacturing and production by enhancing efficiency, reducing human error, and lowering operational costs. However, with these advancements come significant safety concerns. As automation advances, so does the complexity of industrial systems, leading to potential safety concerns. To prevent any accidents, safety measures are implemented in the form of safety switches. These switches aim to create a safe and healthy work environment and prevent any accidents from happening.

How A Safety Switch Works

Safety switches, also known as safety devices, monitor set parameters and take action if those parameters are not met. A simple example of a safety switch in a device is found in some table saws. These saws emit an electrical current through the sawblade. If anything conductive, like a hand, touches the sawblade, it closes a circuit. The switch detects this connection and sends a signal to the brakes, which immediately stops the blade. This concept works

-

- May 23, 2024

The world of automation is an ever-evolving wonderland. When you are operating in this field it is very important to keep up with the competition, and implementing newer and more efficient tools is a great way to do so. Threshold value switches are an essential part of any operation that works with analog signals.

Understanding Threshold Value Switches

Threshold switches are devices that monitor a continuously variable (analog) signal, such as temperature, pressure, or flow. When this analog signal reaches a pre-set level or "threshold," the threshold switch will either activate or deactivate an output, such as turning on a light or triggering an alarm. A threshold value switch ensures operations run smoothly and efficiently. These switches are a critical part of any automation system. They are made with industrial standards, therefore they offer maximum safety and reliability.

How Does A Threshold Value Switch Work?

A threshold value switch functions by continuously comparing one particular