Choosing the Right Connector: Terminal Blocks vs. Wire Nuts for Industrial Wiring!

Electrical connections play a critical role in ensuring the safety, performance, and longevity of wiring systems, especially in demanding industrial settings. Two of the most commonly used connectors are terminal blocks and wire nuts. While both serve to join electrical wires, their features, applications, and durability make them suitable for very different purposes. If you’re considering which to use for your industrial wiring project, this guide our professionals will break down their strengths and limitations, helping you make an informed decision.

Understanding Terminal Blocks and Wire Nuts!

Terminal Blocks

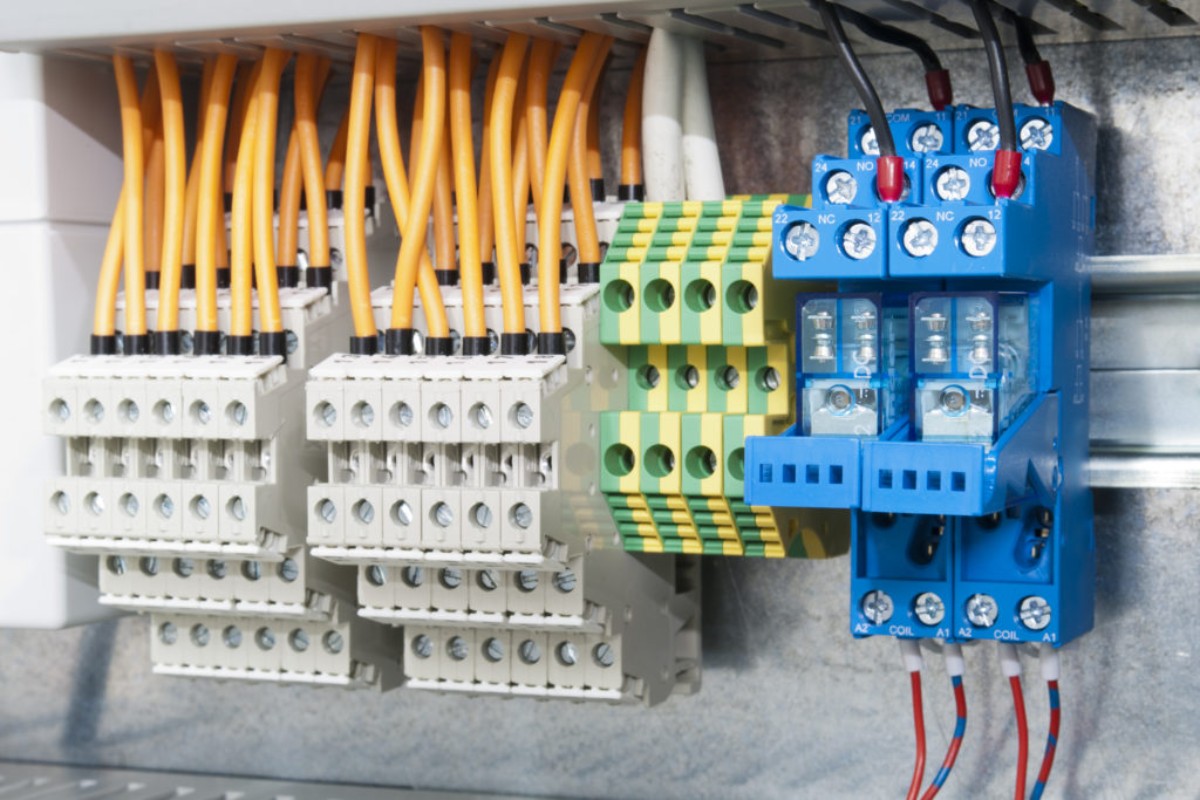

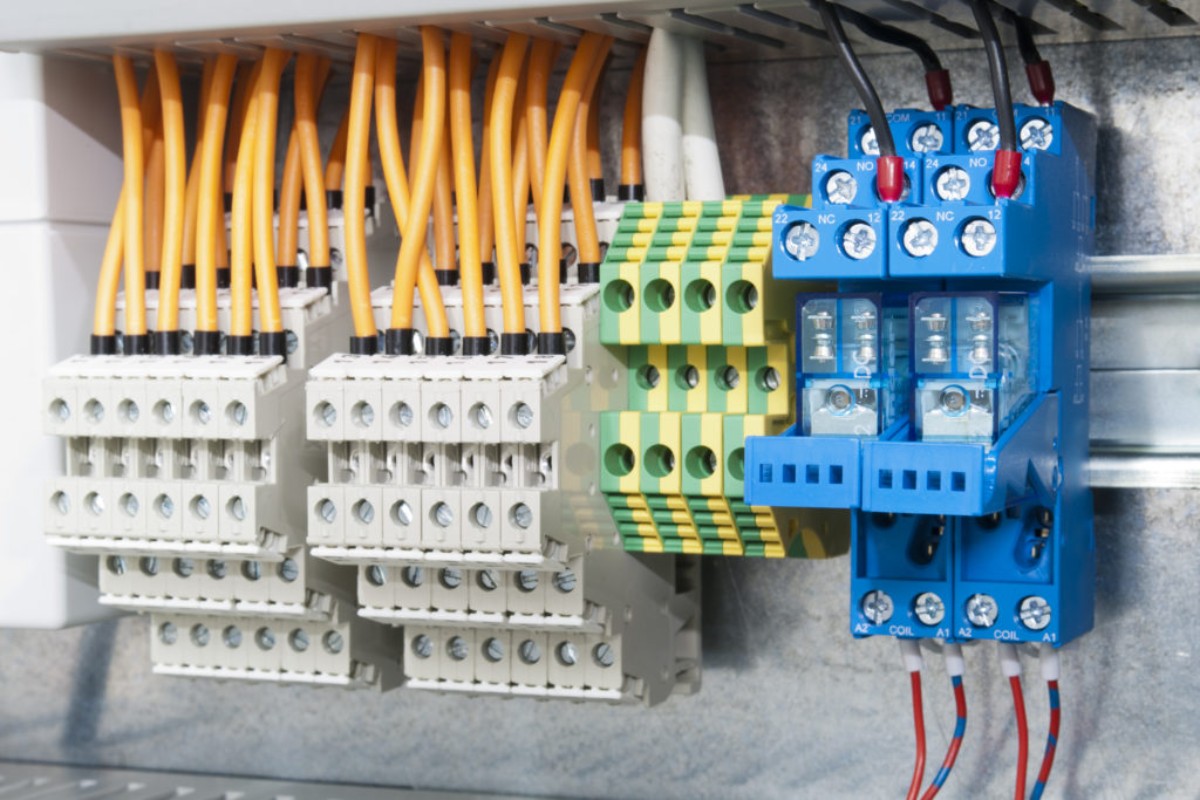

Terminal blocks are modular, insulated devices used to secure multiple wires. These connectors are a staple in industrial and commercial applications, particularly for high-voltage systems. Their design allows for stable and durable connections while offering easy access for testing, inspections, and maintenance. Terminal blocks are commonly found in control panels, industrial machinery, and other large-scale systems that require flexibility and reliability.

Wire Nuts

Wire nuts, in contrast, are simple twist-on connectors typically used in residential or small-scale projects. Their affordability and ease of use make them a popular choice for low-voltage applications, such as connecting light fixtures or household outlets. However, while effective for basic tasks, wire nuts generally fall short in handling the complexities and challenges of industrial wiring.

Key Differences Between Terminal Blocks and Wire Nuts

Application Scope

Wire Nuts:

These connectors are best suited for small-scale, straightforward wiring tasks. For example, they’re commonly used in residential settings to connect wires for lights, switches, or other low-voltage devices.

Terminal Blocks:

Terminal blocks shine in industrial settings, where high-voltage and complex wiring configurations are common. Their modular design and secure connections make them ideal for control panels, industrial machinery, and other large-scale operations.

Safety Considerations

Wire Nuts:

Wire nuts can provide safe connections when installed properly. However, improper installation can lead to issues like loose connections, overheating, or even fire hazards.

Terminal Blocks:

Terminal blocks offer enhanced safety features, such as screw clamps or spring clamps, which securely hold wires in place. This reduces the risk of loose connections and significantly improves safety in high-stakes environments.

Voltage Capability

Wire Nuts:

Designed for low- to medium-voltage applications, wire nuts are not suited for heavy-duty operations or high-voltage systems.

Terminal Blocks:

Built for high-voltage environments, terminal blocks are ideal for industrial applications where electrical loads are much higher and safety is non-negotiable.

Cost

Wire Nuts:

Wire nuts are an inexpensive option, which explains their popularity in residential and DIY projects. Their simple design and mass availability make them cost-effective for smaller tasks.

Terminal Blocks:

While terminal blocks come with a higher upfront cost, their durability, scalability, and reliability often justify the investment for industrial use.

Durability and Lifespan

Both wire nuts and terminal blocks can last a long time if properly installed and maintained. However, terminal blocks are specifically designed to endure harsh industrial conditions, such as extreme temperatures, vibrations, and mechanical stress. This makes them a more reliable choice for long-term use in industrial environments.

Why Terminal Blocks Are Better for Industrial Applications?

In industrial settings, the demands on electrical connections are far greater than in residential environments. Terminal blocks outperform wire nuts in several key areas, making them the preferred choice for complex and high-stakes applications.

Durability

Industrial environments expose wiring systems to extreme conditions, including high temperatures, vibrations, and physical stress. Terminal blocks are built to withstand these challenges, ensuring a stable and long-lasting connection.

Scalability

One of the biggest advantages of terminal blocks is their modular design. This allows for easy expansion or modification of wiring systems. For industries where systems evolve over time, this flexibility is invaluable.

Safety

With secure clamping mechanisms and the ability to handle high-voltage loads, terminal blocks minimize risks associated with loose or faulty connections. Their design ensures wires remain firmly in place, even in challenging conditions.

Maintenance

Terminal blocks are designed for easy access, making them ideal for environments where regular inspections, testing, or troubleshooting are required. This accessibility reduces downtime and simplifies maintenance tasks.

Choose the Right Solution for Your Industrial Needs with Our Help!

Selecting the right connector is essential to the success of your project. Wire nuts may offer an affordable solution for basic, low-voltage tasks, but for industrial environments where safety, reliability, and scalability are non-negotiable, terminal blocks are the clear winner. Their ability to handle high-voltage systems and complex operations makes them an indispensable choice for demanding applications.

To ensure your industrial systems are equipped with the best solutions, rely on US Automation Controls. As a trusted distributor and wholesaler of industrial automation components, we not only provide a wide selection of premium terminal blocks and industrial wiring solutions but also offer expert guidance to help you choose the perfect products tailored to your specific needs. By choosing US Automation Controls as your partner, you can power your operations with confidence, efficiency, and unmatched reliability. Contact us today and let us help you find the solutions you need to meet your industrial challenges head-on!

FAQs

What are terminal blocks, and how do they work?

Terminal blocks are modular, insulated connectors designed to secure multiple wires while providing a stable and durable connection. They are commonly used in industrial settings for high-voltage systems and allow for easy testing, maintenance, and modifications due to their modular design.

What are wire nuts used for?

Wire nuts are twist-on connectors primarily used for low-voltage applications in residential or small-scale projects. They are an affordable option for tasks like connecting wires in light fixtures, switches, and outlets.

Can wire nuts be used in industrial environments?

While wire nuts are effective for small-scale and low-voltage applications, they are not suitable for industrial environments. Their inability to handle high voltages, vibrations, and extreme conditions makes them a less reliable choice for demanding industrial settings.

Why should I choose terminal blocks for industrial use?

Terminal blocks are specifically designed for industrial use. They offer superior durability, scalability, and safety, as well as the ability to handle high-voltage systems. Their modular design makes them ideal for complex systems that require regular maintenance or expansion.