- Technical data - Configuration options:

- e!COCKPIT

- WAGO-I/O-CHECK

- Web-Based Management

- e!RUNTIME library

- CODESYS Library

- Technical data - ETHERNET protocols:

- DHCP

- DNS

- NTP

- FTP

- FTPS

- SNMP

- HTTP

- HTTPS

- SSH

- Environmental requirements - Operating altitude:without temperature derating: 0 ... 2000 m; with temperature derating: 2000 ... 5000 m (0.5 K/100 m); 5000 m (max.)

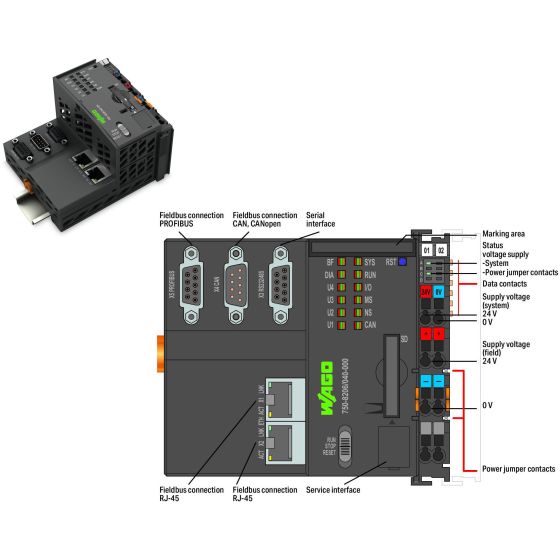

- Technical data - Indicators:LED (SYS, RUN, I/O, CAN, BF, DIA, U1 ... U4) red/green/orange: Status system, program, internal data bus, CANopen, PROFIBUS, PROFIBUS diagnostics, status programmable by user (can be used via CODESYS library); LED (A, B) green: System power supply status, field supply

- Technical data - Number of outgoing power jumper contacts:2

- Technical data - Visualization:Web-Visu

- Technical data - Number of modules per node (max.):64

- Technical data - Memory card slot:Push-push mechanism; Cover lid (sealable)

- Technical data - Supply voltage (system):24 VDC; via pluggable connector (CAGE CLAMP(R) connection); Derating must be observed!

- Technical data - Supply voltage (field):24 VDC; Power supply via pluggable connector (CAGE CLAMP(R) connection); Transmission via power jumper contacts; Derating must be observed!

- Technical data - Current carrying capacity (power jumper contacts):10A

- Mechanical Data - Color:dark gray

- Technical data - CPU:Cortex A8; 600 MHz

- Technical data - Programming environment:

- e!COCKPIT (based on CODESYS V3)

- WAGO-I/O-PRO V2.3 (based on CODESYS V2.3)

- Technical data - Programming languages per IEC 61131-3:

- Instruction List (IL)

- Ladder Diagram (LD)

- Function Block Diagram (FBD)

- Continuous Function Chart (CFC)

- Structured Text (ST)

- Sequential Function Chart (SFC)

- Technical data - Data memory:CODESYS V2: 64 MB; CODESYS V3: 60 MB Program and data memory (dynamically distributed)

- Technical data - Program memory:CODESYS V2: 16 MB; CODESYS V3: 60 MB (Program and data memory (dynamically distributed))

- Technical data - Non-volatile software memory:

- 128Kbytes

- 128.Kbytes

- Technical data - Internal memory (flash):256MB

- Technical data - Main memory (RAM):256MB

- Technical data - Non-volatile hardware memory:128Kbytes

- Technical data - Rated surge voltage:1 kV

- Connection data - Connection type 1:System/field supply

- Connection data - Connection technology: communication/fieldbus:PROFIBUS: 1 x D-sub 9 socket; CANopen: 1 x D-sub 9 plug; Modbus (TCP, UDP): 2 x RJ-45; Modbus RTU: 1 x D-sub 9 socket; RS-232 serial interface: 1 x D-sub 9 socket; RS-485 interface: 1 x D-sub 9 socket; Telecontrol protocol IEC 60870-5-101/-103: 1 x D-sub 9 socket; Telecontrol protocol IEC 60870-5-104: 1 x RJ-45; Telecontrol protocol IEC 61850: 1 x RJ-45; Telecontrol protocol DNP3: 1 x RJ-45 or D-sub 9 socket

- Connection data - Solid conductor:0.25 ... 2.5 mm2 / 24 ... 14 AWG

- Connection data - Fine-stranded conductor:0.25 ... 2.5 mm2 / 24 ... 14 AWG

- Technical data - Power supply efficiency (typ.) at nominal load (24 V):0.9

- Environmental requirements - Mounting position:horizontal (standing/lying); vertical

- Environmental requirements - Mounting type:DIN-35 rail

- Technical data - Baud rate:ETHERNET: 10/100 Mbit/s

- Technical data - Baud rate (communication/fieldbus 1):10/100 Mbit/s

- Physical data - Width:112 mm / 4.409 inches

- Mechanical Data - Housing material:Polycarbonate; polyamide 6.6

- Environmental requirements - Ambient temperature (operation):-40 ... +70 °C

- Technical data - Derating:Derating (supply voltage):

Ambient temperatures under laboratory conditions: (-25 ... +30°%);

for -40 ... +55°°C: 24°V (-25 ... +20°%);

for +55 ... +70°°C: 24°V (-25 ... +10°%);

Lower limit in all temperature ranges: -27.5°% (including 15°% residual ripple) - Environmental requirements - Ambient temperature (storage):-40 ... +85 °C

- Environmental requirements - Relative humidity (without condensation):0.95

- Environmental requirements - Permissible H2S contaminant concentration at a relative humidity

75 %:10ppm - Environmental requirements - Permissible SO2 contaminant concentration at a relative humidity

75 %:25ppm - Environmental requirements - Relative humidity (with condensation):Short-term condensation per Class 3K7/IEC EN 60721-3-3 and E-DIN 40046-721-3 (except for wind-driven precipitation, water and ice formation)

- Environmental requirements - Shock resistance:per IEC 60068-2-27 (15g/11 ms/half-sine/1,000 shocks; 25g/6 ms/1,000 shocks), EN 50155, EN 61373

- Environmental requirements - Vibration resistance:per IEC 60068-2-6 (acceleration: 5g), EN 60870-2-2, IEC 60721-3-1, -3, EN 50155; EN 61373

- Technical data - Current consumption (5 V system supply):600mA

- Technical data - Input current (typ.) at nominal load (24 V):550mA

- Technical data - Total current (system supply):1,700mA

- Commercial data - GTIN:4055140000000

- Commercial data - ETIM 8.0:EC000236

- Commercial data - ETIM 7.0:EC000236

- Commercial data - eClass 10.0:27-24-26-07

- Commercial data - eClass 9.0:27-24-26-07

- Commercial data - Customs tariff number:85371091990

- sku_code:750-8206/040-001

- Commercial data - End of Sale:44939

- Commercial data - End of Delivery:44985

- Commercial data - End of Production:44942

- Commercial data - End of Service and Repair:45716

- Environmental Product Compliance - RoHS Compliance Status:Compliant,With Exemption

- approvals_General approvals:

- IEC - DNV GL Netherlands B.V. - IEC 60870-5-104 ed.2 Client - certificate 10035055-INC 17-1995

- IEC - DNV GL Netherlands B.V. - IEC 60870-5-104 ed.2 Server - certificate 10017175-OPE/INC 16-2021

- KC - National Radio Research Agency - Article 58-2 / Clause 3 - certificate MSIP-REM-W43-PFC750

- UL - UL International Netherlands B.V. (ORDINARY LOCATIONS) - UL 508 - certificate E175199 Sec.1

- approvals_Declarations of conformity and manufacturer's declarations:

- EU-Declaration of Conformity - WAGO GmbH & Co. KG - certificate -

- IEC - DNV GL Netherlands B.V. - IEC 60870-5-104 ed.2 Server - certificate 10017175-OPE/INC 16-2021

- IEC - DNV GL Netherlands B.V. - IEC 60870-5-104 ed.2 Client - certificate 10035055-INC 17-1995

- approvals_Approvals for marine applications:

- ABS - American Bureau of Shipping - certificate 22-2208829-PDA

- PRS - Polski Rejestr Statkow - certificate TE/1099/880590/23

- Environmental Product Compliance - RoHS Exemption:

- 6(c)

- 7(a)

- 7(c)-I

- 7(c)-II

- approvals_Approvals for hazardous areas:

- ATEX - TUEV Nord Cert GmbH - EN 60079-0 - certificate TUEV 17 ATEX 193969X (II 3 G Ex ec IIC T4 Gc)

- CCC - CNEX - CNCA-C23-01 - certificate 2020312310000214 (Ex ec IIC T4 Gc)

- EAC - Brjansker Zertifizierungsstelle - TP TC 012/2011 - certificate EAC RU C-DE.AM02.B.00163/19 (2Ex e IIC T4 Gc X)

- IECEx - TUEV Nord Cert GmbH - IEC 60079-0 - certificate IECEx TUN 16.0046X (Ex ec IIC T4 Gc)

- UKEx - WAGO GmbH & Co. KG - EN 60079-0 - certificate UKCA_WAGO22UKEX005X_ec

- UL - Underwriters Laboratories Inc. (HAZARDOUS LOCATIONS) - UL 121201 - certificate E198726 Sec.1

- Environmental requirements - Exposure to pollutants:Per IEC 60068-2-42 and IEC 60068-2-43

- Mechanical Data - Conformity marking:CE

- Technical data - Telecontrol protocols:

- IEC 60870-5-101/-103/-104

- IEC 61400-25

- IEC 61850-7

- DNP3

- Technical data - Ratings per:IEC/EN 60664-1

- Commercial data - Country of origin:DE

- Environmental requirements - Pollution degree:2 per IEC 61131-2

- Technical data - Type of memory card:SD and SDHC up to 32 GB (all guaranteed properties only valid with WAGO's memory card)

- Technical data - Operating system:Real-time Linux (with RT-Preempt patch)

- ACCESSORIES_Markingaccessories:

- 2009-145

- 2009-145/000-002

- 2009-145/000-005

- 2009-145/000-006

- 2009-145/000-007

- 2009-145/000-012

- 2009-145/000-023

- 2009-145/000-024

- 248-501

- 248-501/000-002

- 248-501/000-005

- 248-501/000-006

- 248-501/000-007

- 248-501/000-012

- 248-501/000-017

- 248-501/000-023

- 248-501/000-024

- 750-103

- 750-107

- ACCESSORIES_Carrierrail:

- 210-112

- 210-113

- 210-114

- 210-115

- 210-118

- 210-196

- 210-197

- 210-198

- 210-504

- 210-505

- 210-506

- 210-508

- ACCESSORIES_ShieldConnection:

- 790-108

- 790-116

- 790-124

- 790-140

- 790-208

- 790-216

- 790-220

- ACCESSORIES_SystemBox:

- 850-814/002-000

- 850-815/002-000

- 850-816/002-000

- 850-817/002-000

- 850-825

- 850-826

- 850-826/002-000

- 850-827

- 850-827/002-000

- 850-828

- 850-828/002-000

- 850-834

- 850-835

- 850-836

- ACCESSORIES_WiringAndConnectors:

- 750-960

- 750-963

- 750-975

- 750-977/000-011

- 750-977/000-012

- 750-977/000-021

- 750-977/000-022

- 750-978/000-011

- 750-978/000-012

- 750-978/000-021

- 750-978/000-022

- 750-979/000-011

- 750-979/000-012

- 750-979/000-021

- 750-979/000-022

- ACCESSORIES_Communication:

- 750-923

- 750-923/000-001

- mandatory_ACCESSORIES_MemoryCard:

- 758-879/000-001

- 758-879/000-2108

- manufacturer_description:Controller PFC200; 2 x ETHERNET, RS-232/-485, CAN, CANopen, PROFIBUS Slave; Telecontrol technology; Extreme

- picture_filename_1:1024-0200001d000218ee000100b6-DE.jpg

- picture_zoom_filename_1:2000-0200001d000218ee000100b6-DE.jpg

- picture_filename_2:1024-0200001e0000819f000200b6-EN.jpg

- picture_zoom_filename_2:2000-0200001e0000819f000200b6-EN.jpg

- Physical data - Height:100 mm / 3.937 inches

- manufacturer_detailed_description:

The PFC200 Controller is a compact PLC for the modular WAGO I/O System. Besides network and fieldbus interfaces, the controller supports all digital, analog and specialty modules found within the 750/753 Series.

Two ETHERNET interfaces and an integrated switch enable line topology wiring.

An integrated Webserver provides user configuration options, while displaying PFC200 status information.

Besides the processing industry and building automation, typical applications for the PFC200 include standard machinery and equipment control (e.g., packaging, bottling and manufacturing systems, as well as textile, metal and wood processing machines).

Programming per IEC 61131-3

- Programmable via WAGO-I/O-PRO V2.3

- Direct connection of WAGO's I/O modules

- 2 x ETHERNET (configurable), RS-232/485, CAN, CANopen, PROFIBUS DP Slave

- Linux operating system with RTâ€Preempt patch

- Configuration via CODESYS or Web-Based Management interface

- Maintenance-free

The device is ideal for operation in extreme environments thanks to:

- An extended temperature range

- Greater immunity to impulse voltages and electromagnetic interference

- Higher vibration and shock resistance

- Physical data - Depth:71.9 mm / 2.831 inches

- picture_filename_3:1024-020000040002c6e6000400b6-EN.jpg

- picture_zoom_filename_3:2000-020000040002c6e6000400b6-EN.jpg

- Physical data - Depth from upper-edge of DIN-rail:64.7 mm / 2.547 inches

- Environmental requirements - Protection type:IP20

- Environmental requirements - EMC emission of interference:per EN 61000-6-3, -4, EN 61131-2, EN 60255-26, marine applications, EN 60870-2-1, EN 61850-3, EN 50121-3-2, EN 50121-4, -5

- Environmental requirements - EMC immunity to interference:per EN 61000-6-1, -2; EN 61131-2; marine applications; EN 50121-3-2; EN 50121-4, -5; EN 60255-26;

EN 60870-2-1; EN 61850-3; IEC 61000-6-5; IEEE 1613; VDEW: 1994 - Mechanical Data - Weight:262g

- Technical data - Communication:

- PROFIBUS

- CANopen

- Modbus (TCP, UDP)

- ETHERNET

- EtherNet/IPTM Adapter (slave), library for e!RUNTIME

- Modbus RTU

- RS-232 serial interface

- RS-485 interface

- MQTT

- Telecontrol protocols

- Environmental requirements - Fire load:3.303MJ

- Technical data - Transmission medium (communication/fieldbus):ETHERNET: Twisted Pair S-UTP; 100 Ω; Cat. 5; 100 m maximum cable length

- Technical data - Input and output process image (internal) max.:1000 words/1000 words

- Technical data - Input and output process image (Modbus(R)) max.:CODESYS V2: 1000 words/1000 words; CODESYS V3: 32000 words/32000 words

- Technical data - Input and output process image (CAN) max.:2000 words/2000 words

- Primary brand: Wago

- Functions:

- Programmable Logic Controller (PLC) CPU unit

- MQTT

- DHCP

- DNS

- NTP

- FTP

- FTPS

- SNMP

- HTTP

- HTTPS

- SSH

- Design:

- extended temperature range

- Telecontrol technology

- Supply voltage (DC): 18-31.2Vdc via wiring (24Vdc nom.)

- Processor type: ARM Cortex-A8 600MHz

- Programming languages:

- Instruction List (IL)

- Ladder Diagram (LD)

- Function Block Diagram (FBD)

- Continuous Function Chart (CFC)

- Structured Text (ST)

- Sequential Function Chart (SFC)

- Programming environment

- - e!COCKPIT (based on CODESYS V3)

- - WAGO-I/O-PRO V2.3 (based on CODESYS V2.3)

- Configuration options

- - e!COCKPIT

- - WAGO-I/O-CHECK

- - Web-Based Management

- - e!RUNTIME library

- - CODESYS Library

- Memory capacity:

- 256MB memory (RAM)

- 256MB internal memory (flash)

- 128kB non-volatile memory (software)

- 16MB (program memory; CODESYS V2)

- 64MB (data memory; CODESYS V2)

- 60MB (distributed dynamically between program memory and data memory; e!RUNTIME)

- 128kB non-volatile memory (hardware)

- Connection capacity: 64 x connections per node

- Connection type:

- 2 x RJ45 connectors (fieldbus)

- 3 x 9-pin D-sub connectors

- CAGE CLAMP 2-pin (system)

- CAGE CLAMP 4-pin (field)

- Mounting mode: DIN-35 rail

- Speed:

- 10Mbit/s

- 100Mbit/s

- Dimensions: H100mm x W112mm x D71.9mm

- Net Width (mm): 112mm

- Material: Polycarbonate (PC) / Polyamide (PA) 6.6 housing

- Ambient air temperature for operation: -40°C...+70°C

- Ambient air temperature for storage: -40°C...+85°C

- Humidity: 95% relative humidity (RH; non-condensing)

- Mechanical resistance:

- Vibration resistance according to EN 60068-2-6 -- 5g

- Shock resistance according to EN 60068-2-27 --15g (11ms / half-sine / 1000 shocks)

- Shock resistance according to EN 60068-2-27 --25g (6ms / 1000 shocks)

- Current consumption:

- 550mA (24Vdc; at nominal load)

- 600mA (5Vdc; system supply)

- 1700mA (system supply)

- GTIN code: 4055140000000

- ETIM code: EC000236

- eClass code: 27-24-26-07

- Customs Tariff Number: 85371091990

- Order code / Manufacturer SKU: 750-8206/040-001

- Manufacturer product status: Discontinued

- Equivalent to: 7508210000000

- Product lifecycle information:

- End of life announced on -- 2023 Jan 12

- End of sales -- 2023 Jan 13

- End of production -- 2023 Jan 16

- End of delivery -- 2023 Feb 28

- End of service and repair -- 2025 Feb 28

- Compliant with standard(s):

- Telecontrol protocols

- - IEC 60870-5-101

- - IEC 60870-5-103

- - IEC 60870-5-104

- - IEC 61400-25

- - IEC 61850-7

- - DNP3

- EMC immunity to interference

- - EN 61000-6-1

- - EN 61000-6-2

- - EN 61131-2

- - marine applications

- - EN 50121-3-2

- - EN 50121-4

- - EN 50121-5

- - EN 60255-26

- - EN 60870-2-1

- - EN 61850-3

- - IEC 61000-6-5

- - IEEE 1613

- - VDEW (1994)

- EMC emission of interference

- - EN 61000-6-3

- - EN 61000-6-4

- - EN 61131-2

- - EN 60255-26

- - marine applications

- - EN 60870-2-1

- - EN 61850-3

- - EN 50121-3-2

- - EN 50121-4

- - EN 50121-5

- General approvals

- - IEC - DNV GL Netherlands B.V. - IEC 60870-5-104 ed.2 Client - certificate 10035055-INC 17-1995

- - IEC - DNV GL Netherlands B.V. - IEC 60870-5-104 ed.2 Server - certificate 10017175-OPE/INC 16-2021

- - KC - National Radio Research Agency - Article 58-2 / Clause 3 - certificate MSIP-REM-W43-PFC750

- - UL - UL International Netherlands B.V. (ORDINARY LOCATIONS) - UL 508 - certificate E175199 Sec.1

- Declarations of conformity and manufacturer's declarations

- - EU-Declaration of Conformity - WAGO GmbH & Co. KG

- - IEC - DNV GL Netherlands B.V. - IEC 60870-5-104 ed.2 Server - certificate 10017175-OPE/INC 16-2021

- - IEC - DNV GL Netherlands B.V. - IEC 60870-5-104 ed.2 Client - certificate 10035055-INC 17-1995

- Approvals for marine applications

- - ABS - American Bureau of Shipping - certificate 22-2208829-PDA

- - PRS - Polski Rejestr Statkow - certificate TE/1099/880590/23

- Approvals for hazardous areas

- - ATEX - TUV Nord Cert GmbH - EN 60079-0 - certificate TUV 17 ATEX 193969X (II 3 G Ex ec IIC T4 Gc)

- - CCC - CNEX - CNCA-C23-01 - certificate 2020312310000214 (Ex ec IIC T4 Gc)

- - EAC - Brjansker Zertifizierungsstelle - TP TC 012/2011 - certificate EAC RU C-DE.AM02.B.00163/19 (2Ex e IIC T4 Gc X)

- - IECEx - TUV Nord Cert GmbH - IEC 60079-0 - certificate IECEx TUN 16.0046X (Ex ec IIC T4 Gc)

- - UKEx - WAGO GmbH & Co. KG - EN 60079-0 - certificate UKCA_WAGO22UKEX005X_ec

- - UL - Underwriters Laboratories Inc. (HAZARDOUS LOCATIONS) - UL 121201 - certificate E198726 Sec.1

- RoHS compliant with exemption (6(c) / 7(a) / 7(c)-I / 7(c)-II)

- Location of origin: Germany

- Degree of pollution: 2

- Storage type: SD and SDHC card slot (up to 32GB)

- Operating System (OS): Real-time Linux (with RT-Preempt patch)

- Cross-sells with:

- 758-879/000-001

- 758-879/000-2108

- 2009-145

- 2009-145/000-002

- 2009-145/000-005

- 2009-145/000-006

- 2009-145/000-007

- 2009-145/000-012

- 2009-145/000-023

- 2009-145/000-024

- 210-112

- 210-113

- 210-114

- 210-115

- 210-196

- 210-197

- 210-198

- 210-504

- 210-505

- 210-506

- 210-508

- 248-501

- 248-501/000-002

- 248-501/000-005

- 248-501/000-006

- 248-501/000-007

- 248-501/000-012

- 248-501/000-017

- 248-501/000-023

- 248-501/000-024

- 750-103

- 750-107

- 750-923

- 750-923/000-001

- 750-960

- 750-963

- 750-975

- 750-977/000-011

- 750-977/000-012

- 750-977/000-021

- 750-977/000-022

- 750-978/000-011

- 750-978/000-012

- 750-978/000-021

- 750-978/000-022

- 750-979/000-011

- 750-979/000-012

- 750-979/000-021

- 750-979/000-022

- 790-108

- 790-116

- 790-124

- 790-140

- 790-208

- 790-216

- 790-220

- 850-814/002-000

- 850-815/002-000

- 850-816/002-000

- 850-817/002-000

- 850-825

- 850-826

- 850-826/002-000

- 850-827

- 850-827/002-000

- 850-828

- 850-828/002-000

- 850-834

- 850-835

- 850-836

- Level 1 category: Automation components

- Level 2 category: Programmable Logic Controllers & components

- Level 3 category: CPU Units

- Product title: Programmable Logic Controller (PLC) CPU unit - Wago (PFC200 XTR series)